America visiting ASA in Austria

ASA the Factory

ASA Astrosysteme GmbH is located just outside the town of Neumarkt in Upper Austria. It is a 2 ½ hour drive from the capital of Austria, Vienna. ASA is well-known for producing world-class astronomical telescope systems. Over the past two decades, they have become a vertically integrated company with complete control over the mechanical and optical designs, fabrication, and manufacturing of large observatory systems. These systems are deployed around the globe including Europe, Asia, and North America.

This is the second time I visited ASA. My last visit was five years ago, and the transformation that occurred at the company since that time is nothing short of remarkable! The staff size, facility, manufacturing capabilities, and telescope sizes produced have all grown substantially. It took a full day just to briefly meet the administration staff which included the Sales team, the Marketing group, finance, and HR and much more.

Similar to many businesses in the near post-Covid world, many of the employees at ASA work from remote locations at different times. At any time, this may include support, mechanical engineering, software engineering and optical engineering. Of course, many trades do not lend themselves to this mode of work and those people are regularly at the ASA facility.

ASA CNC Machining Center

The CNC Machining Center is located next to the Telescope Assembly Hall and produces both standard and custom telescope parts on a regular basis. The area is packed with CNC machines of all types. Each of the CNC machines are constantly in motion producing components; many are required to run overtime in order to keep up with production. Regardless of how early or late I was at the facility – I never saw the machining center inactive!

Every telescope and mount component of significance is machined at the Machining Center. They control the quality and delivery schedule of components which is one of the reasons their lead times are incredibly short. ASA maintains a large supply of raw materials at the site which also ensures short lead times and rapid responses to priority adjustments that have a habit of coming up. They also produce custom telescope parts and custom camera adapters specific to each order. During my visit, they were making the largest custom color filter wheels I have ever seen. The offices of the Mechanical Design team were close to the CNC Machine Center for those time when questions arise.

ASA CNC Machining Center

ASA Engineering Offices

The Engineering Offices are strategically located between the CNC Machining Center and the Telescope Assembly Hall. The offices are a hub of activity related to every aspect of telescope and mount design. That includes electrical and mechanical drawings, electrical and mechanical design, testing and installations.

The Engineering Group is also responsible for custom design such as camera adapters, color filter wheels and a host of other required parts for order fulfillment. Everything from adapter drawings to future designs are worked on in these rooms. Most of what I viewed there cannot be shared. This is also where I had a glimpse into the future: There are several very exciting new products on the horizon. Stay tuned!

ASATelescope Assembly Hall

The Production and Assembly workers were a marvel to watch. These fellows were in constant motion while I was there – seamlessly moving from motor assemblies in the morning, to optical installations in the afternoon. In production at that time were various optical tube assemblies and full observatory systems including: 400mm OTAs, 800mm OTA, several 1-meter OTAs, plus two massive soon-to-be-delivered 1.5-meter OTAs.

ASA Outside Telescope System Testing

The outside testing area is located next to the main building but close enough to the assembly area that completed telescope systems could be moved via fork-lift out on the day that testing will occur. System Testing itself must be done under clear skies so there is a need to have staff available regardless of the day of the week or time of year. Testing goes fairly quickly but that still means a late night for the guys.

By the time the OTA or Telescope System is brought outside, it is nearly 100% assembled. The optics and direct drive will be fully functioning before testing occurs. Testing includes pointing accuracy, tracking accuracy, collimation and final optical quality evaluations. Should more time be required than a single night, there is a very large clamshell dome that can be used to protect optics that remain outside.

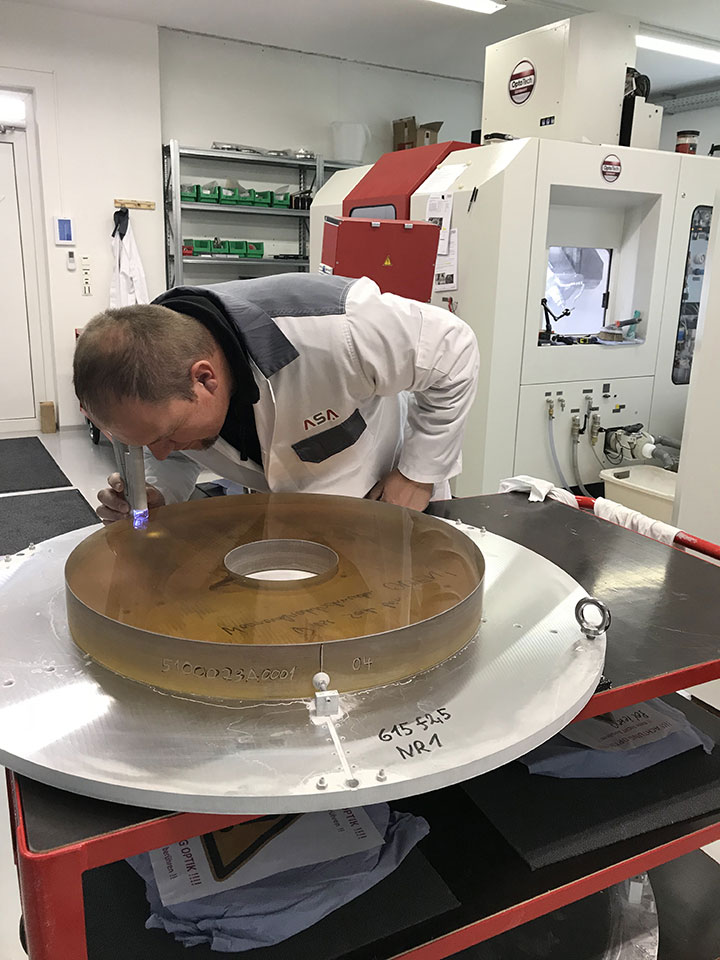

ASA Optical Laboratory

The Optical Lab and Testing Silo facilities are a short drive from the main ASA site. As I mentioned previously – ASA had grown over the years since my last visit. By far the largest improvements have occurred at the Optical Lab. Not only had the capabilities and capacities improved, the number optics being processed at any one time has increased as well. The lab can produce a world-class quality 1-meter optic in under 3 months. As with the machined parts, the lab has a large source of raw materials to choose from (Schott or CDGM glass catalogue).

The optical laboratory consisted on several buildings where the heart of the telescope literally takes shape. Each optics travels through a series of iterative processes that bring it from raw material to completion. Every optical step is performed in-house with quality feedback loops along the way ensuring the finest available optics available by completion.

By this time, you might understand that I was impressed with the level of professionalism and dedication that I witnessed at ASA. The Optical Laboratory however completely bowled me over with their capabilities and the sheer number of optics that were in process at any given time. It was a juggling act second to none.

A new larger wing of the facility was under construction while I was there – this will more than double the footprint of the Optical facility. There is also a portion of the building set aside with rooms for staff and guests for overnight stays when the need presents itself.

ASA Optical Laboratory

ASATesting Silo

The Testing Silo is a specially made building adjacent to the Optical Lab. This measurement tower is used to produce high-quality Computer-Generated Holograms using a vibration-immune interferometer. These measurements are feed into their CNC based state-of-the-art polishing robots to precisely remove surface errors like astigmatism in the continued quest for optical perfection. In this way – ASA is able to produce nearly any free form surface such as an off-axis parabola and even more complicated shapes.

Fabrication of world-class optics is only possible with accurate feedback via high-quality testing which is why ASA invested in high quality test equipment, and optical robots. Their optical processes utilize a precision iterative process to remove measurable errors – allowing them to achieve the highest quality optical figures available.

Summary of my week ASA - Quality matters

I left Austria with a renewed respect for ASA’s growth and constant push towards mechanical & optical perfection; everyone at the company seemed to have the same goal. During the visit I quickly got the sense that Quality, in all its forms, is a common denominator at ASA Astrosysteme GmbH. It was a pleasure meeting the team!

My special thanks to Egon Döberl, Michael Landl, Dietmar Weinzinger, and Wolfgang Promper.

Summary of my week ASA - Quality matters

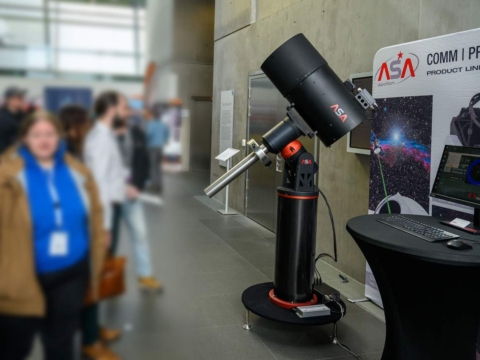

ASA Impressions

ASA In-house production

The competent partner that provides you with the whole package – ASA, guarantees the highest standard! Interferometric metrology, CNC machining, meter class optics, light weight mirrors, telescope systems, ground stations, assembly, factory testing and commissioning, everything is done by ASA itself.